Workforce optimization is quickly becoming mission-critical for retailers — especially food retailers and other commercial facilities that depend on complex technical equipment like refrigeration units and HVAC systems to keep operations running. With profit margins in grocery averaging just 1–2%, even small inefficiencies in how technical teams are managed can erode an organization’s bottom line fast.

In fact, industry projections show there could be 20 job openings for every 1 new skilled trades worker in coming years, making it more important than ever to get the most out of your existing technician workforce.

In this article, we’ll explore what workforce optimization really means, how it differs from traditional workforce management, the stages of effective workforce planning, and field-tested workforce optimization strategies you can start implementing today.

What Is Workforce Optimization?

What is the meaning of workforce optimization?

Workforce optimization (WFO) is a strategic approach to improving how effectively an organization’s employees are managed and deployed. It combines elements of human resources, operations, and quality management to ensure you have the right people with the right skills in the right roles at the right times.

In short, workforce optimization ensures an organization is utilizing its people as efficiently and effectively as possible to meet its goals.

Key outcomes of workforce optimization include:

- Higher employee engagement and retention

- Improved productivity and service quality

- Lower operational costs

What is the difference between workforce management and workforce optimization?

It’s easy to confuse workforce management (WFM) with workforce optimization. Both seek to maximize employee productivity, but there are important differences.

Workforce management typically refers to the day-to-day processes of staff scheduling, time and attendance tracking, and making sure the right employees are in the right place at the right time to meet operational needs.

Workforce optimization, on the other hand, is a broader, more holistic strategy. It encompasses workforce management but also integrates performance coaching, quality assurance, continuous enhancement, and technology to help employees and departments operate at peak performance.

For example, a workforce optimization initiative might include a new mentoring program to improve work quality, or analytics to identify process bottlenecks — efforts beyond the scope of basic WFM. Together, WFM ensures the operation runs day-to-day, while WFO ensures the operation keeps getting better day-by-day.

What are the stages of workforce planning?

Workforce planning is a key practice within workforce optimization. It involves forecasting and preparing for your organization’s current and future staffing needs.

The process can be broken down into five clear stages:

- Assess current workforce: Evaluate your current workforce’s capabilities, demographics, and capacity. This includes assessing employees’ skills, experience levels, roles, and retirement projections to understand the talent you have on hand.

- Forecast future needs: Determine the workforce you will need to achieve your business goals. Consider upcoming projects, growth plans, or new technologies, and forecast the number of people and the specific skills required in the future.

- Identify gaps: Compare your current supply to future demand in order to identify gaps and pinpoint labor skill shortages (or surpluses). For instance, are you short on technicians for a new region or lacking certain skills or qualifications (e.g., refrigeration EPA certifications)?

- Develop action plans: Develop action plans to bridge the gaps. This could include recruiting new technicians, upskilling existing staff, succession planning for retiring experts, and outsourcing certain tasks. Assign timelines and responsibilities for implementing these solutions.

- Implementation and monitoring: Put the workforce plan into action and track progress. Monitor key metrics like attrition, time-to-hire, training completion, and performance improvements. Continually revisit and adjust the plan as conditions change.

By following these stages, organizations can ensure they have the right workforce in place to meet both present and future operational demands.

Why Is Workforce Optimization So Important in Technical Industries?

Workforce optimization is important in any business, but it’s especially critical in facilities management for sectors like grocery retail, restaurants, manufacturing, and hospitality, which rely heavily on skilled technicians to maintain equipment and infrastructure. In these sectors, a well-optimized technical workforce can make the difference between smooth operations and costly disruptions.

1. Talent Gaps and Skilled Labor Shortages

Technical industries are facing serious skilled labor shortages. Many tradespeople are retiring faster than new ones are entering the field, creating a talent gap. For example, in sectors like food retail, where refrigeration systems are essential, finding experienced refrigeration technicians is becoming increasingly difficult.

Optimizing the workforce you do have — through training, better hiring, and smarter scheduling — helps ensure you’re getting maximum retention and productivity from a limited pool of talent. But it’s not just about managing the team you already have — it also includes how you attract, hire, and onboard new talent.

2. High Costs of Downtime and Mistakes

The cost of downtime and mistakes in technical fields is extremely high, especially in industries with razor-thin margins. Take the supermarket space for example: a full-store refrigeration outage can lead to over $10,000 in lost product sales.

Equipment downtime also diverts employees from their normal duties and can hurt the customer experience, directly translating into not just lost product but lost sales and profit.

3. Safety and Compliance Requirements

Technical teams often have to meet strict safety and compliance standards. In food retail, for example, refrigeration systems must maintain specific temperature ranges to comply with health codes, while OSHA sets detailed protocols for equipment handling and workplace safety.

A well-trained and well-coordinated team (a result of strong workforce optimization) is better equipped to maintain compliance, thus avoiding costly fines and accidents.

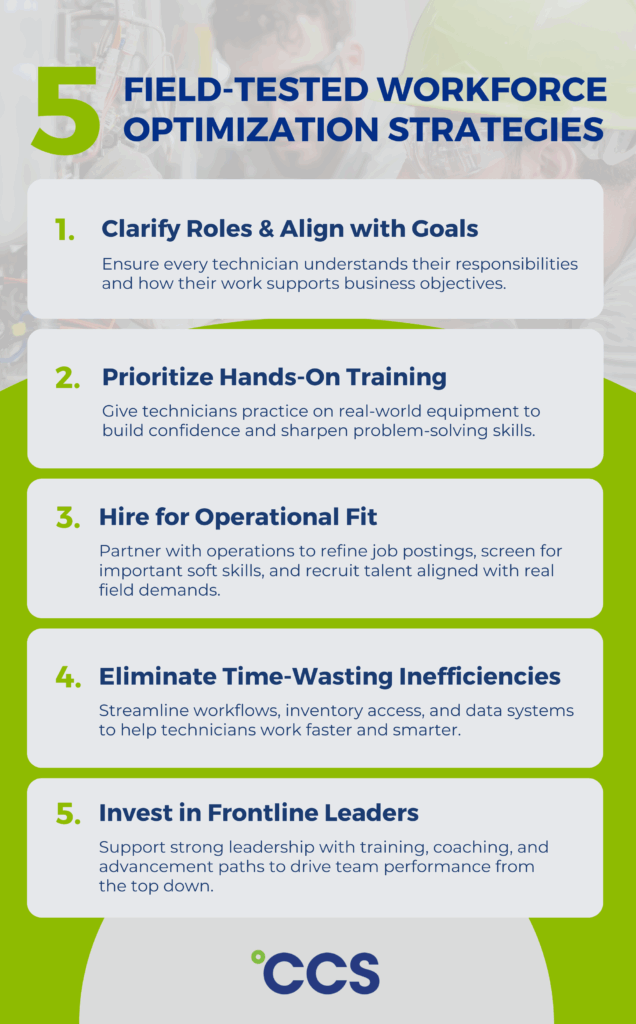

5 Field-Tested Workforce Optimization Strategies

To help your technical operations perform at their peak, consider these five proven workforce optimization strategies.

1. Strengthen Role Clarity and Alignment

One of the simplest yet most impactful steps is ensuring every technician has crystal-clear role definition and alignment with business goals. Lack of role clarity can cause frustration, duplication of work, or important tasks “falling through the cracks.”

To address this, evaluate each technical job description and clarify responsibilities, expectations, and how that role supports the organization’s objectives. Encourage managers to reinforce alignment in regular check-ins by connecting technicians’ daily work to bigger-picture outcomes like customer satisfaction or cost savings.

Alignment pays off — teams that regularly communicate role expectations and business goals enjoy stronger employee satisfaction and retention rates. Technicians want to succeed; giving them a clear playbook for their role is a win-win for them and the company.

2. Build a Hands-On Skills Development Track

Technical teams thrive when their skills keep up with changing technology. Rather than relying on ad-hoc on-the-job training, build a structured, hands-on training and development program for your technicians.

This means going beyond online modules — provide real equipment and simulations so techs can practice in a low-risk environment. There’s no substitute for practical experience when it comes to the trades.

City Consulting Services (CCS) exemplifies this approach through its First Coast Technical Academy in Jacksonville, FL, a dedicated training center designed to upskill technicians. As George Campbell, the facility’s director of technical services, explains, “We take the exact or similar equipment the technicians will be working on in the field and customize a hands-on training experience as well as the curriculum to support it.”

The result, George says, is technicians who are more confident problem-solvers and better troubleshooters when they return to the field.

| Read more: For a deeper dive into developing a hands-on training program, check out our guide on technical workforce strategies. |

3. Rewire Your Hiring Process for Operational Fit

Too often, recruiting and HR teams work in a silo, forwarding candidates to hiring managers without fully vetting for the right skills or cultural fit. To optimize your workforce, it’s time to rewire your hiring process so that your talent acquisition is deeply connected to your operations department.

Start by collaborating closely with your operations leaders (or a consulting partner with technical hiring expertise) to create better job postings, screening criteria, and skills assessments. Additionally, look for soft skills like problem-solving and customer service mindset, which are crucial for top-performing techs.

It’s also beneficial to seek out recruiters or talent partners who have an intimate understanding of your industry. When HR understands the day-to-day challenges of, say, a refrigeration technician, they can better identify candidates who will thrive in that environment.

| Read more: For more tips on recruiting effectively, see our guide on technician recruitment best practices. |

4. Streamline Processes That Waste Technicians’ Time

You can’t optimize workforce output if job orders are delayed, tools are missing, or communication is disjointed. Implementing facilities management best practices creates the operational foundation for workforce efficiency:

- Strengthen your supply chain: Implement just-in-time inventory systems for commonly needed parts in order to reduce delays caused by missing parts, tools, or materials — a major source of wasted technician time.

- Strengthen asset management: Use digital asset databases accessible via mobile devices to give technicians quick access to asset histories, locations, and specs, so they’re not troubleshooting blind.

- Leverage data analytics: Use pattern recognition tools to identify recurring issues and prioritize high-impact work, helping techs avoid busywork and prevent repeat failures.

- Implement EMS platforms: Enable remote monitoring and diagnostics, reducing unnecessary site visits or manual checks. Technicians arrive prepared with the right tools and parts.

- Adopt an integrated approach to facilities management: Outsourcing facilities management to an IFM provider centralizes communication, reduces rework, and streamlines operations across all trades by increasing service reliability and leveraging cross-functional expertise.

- Implement AI-powered parts prediction tools: Advanced systems can predict part failures before they occur, allowing proactive replacement during scheduled maintenance windows — instead of emergency calls during off-hours.

- Use AI in work order management systems: Intelligent routing and scheduling systems consider technician skills, location, and parts availability to optimize daily workflows and minimize windshield time.

5. Invest in Frontline Leadership

Technical teams often focus on the “boots on the ground,” but don’t forget that great teams need great leaders. Investing in your frontline leadership is a powerful workforce optimization strategy because skilled, engaged leaders will amplify all the other efforts (training, process improvement, etc.) and drive the team forward.

A few actionable steps for investing in leadership include:

- Revisit and clarify leadership roles and job descriptions

- Outline clear advancement paths

- Implement succession planning

- Provide formal leadership training programs

- Encourage mentoring and coaching

In the long run, this investment in leadership trickles down to every level of your workforce, creating a culture of efficiency, development, and accountability — the very essence of workforce optimization.

Workforce Optimization: Putting It All Together

By clarifying roles, continually developing technical skills, hiring smarter, streamlining workflows, and empowering your leaders, you can take your technical workforce to the next level — and reap the rewards in terms of productivity, cost savings, reputation, and more.

City Consulting Services (CCS) brings decades of facilities management experience to help organizations implement the workforce optimization strategies above. Our team of experts has recruited and trained thousands of technical staff in highly competitive markets, and we’ve developed and refined the processes that drive operational excellence. Whether you’re looking to reduce turnover among HVAC technicians or improve the efficiency of maintenance across hundreds of retail locations, we can partner with you to develop a solution tailored to your needs. Learn more about City Consulting Services.

2016: City US is established in North America, in partnership with Southeastern Grocers (SEG), servicing over 750 supermarkets across 7 southern states.

2016: City US is established in North America, in partnership with Southeastern Grocers (SEG), servicing over 750 supermarkets across 7 southern states. 1985: Willie and Susan Haughey establish City Refrigeration Holdings (UK) Ltd in Glasgow, UK.

1985: Willie and Susan Haughey establish City Refrigeration Holdings (UK) Ltd in Glasgow, UK. 2009: City Australia launches in Melbourne, in partnership with Coles, servicing over 700 supermarkets across the country.

2009: City Australia launches in Melbourne, in partnership with Coles, servicing over 700 supermarkets across the country. 2015: City Asia launches in Kuala Lumpur, Malaysia, in partnership with Dairy Farm, servicing over 205 supermarkets across the region.

2015: City Asia launches in Kuala Lumpur, Malaysia, in partnership with Dairy Farm, servicing over 205 supermarkets across the region.