Facilities management checklists are commonly employed as a vital preventive measure prior to kicking off the summer and winter seasons. But in the food retail industry, there’s another critical season that requires the attention of FM teams in advance — the holidays.

Kicking off with Labor Day in early September and extending through New Year’s Day, the holiday season requires a substantial escalation in food preparations by supermarket staff. This flurry of cooking, baking, and frying can take a toll on commercial food equipment, and should an asset break down in the midst of this heightened demand — such as an oven going down on Thanksgiving — the result can be catastrophic for a store in terms of both customer experience and revenue.

By implementing a preventive maintenance (PM) program in the weeks before Labor Day, facilities management leaders can help ensure food equipment is ready for the increased demand of the holidays while improving work-life balance for their teams.

To make sure your grocery store commercial food equipment is ready to go this year, we’ve put together the following food equipment facilities management checklist.

Food Equipment Preventive Maintenance: 4 Considerations for Facilities Managers

“The key to maximizing food equipment uptime during the holidays is following food prep PMs all year long, but it’s important to ramp up PMs during the summertime,” says Cristee Monahan, VP of Central Operations for City. “During this time, our MSTs [multi-skilled technicians] check all equipment preemptively to make sure everything is in tip-top condition. Our goal is to be completed and ready to go as we get into Labor Day.”

As with all preventive maintenance checklists, inspections and maintenance of food equipment — anytime of year — are centered on four questions:

1. Is it safe?

Safety should always be the number one priority when it comes to food equipment. This involves:

- Regular maintenance and inspections of all food equipment in order to identify and address any potential safety issues promptly

- Adhering to manufacturer guidelines for maintenance schedules and procedures

- Ensuring proper sanitation practices, including regular cleaning and sanitizing of equipment surfaces and parts that come into contact with food, to help prevent contamination and the spread of pathogens

- Investing in energy-efficient equipment to reduce the risk of overheating or electrical malfunctions

- Staying informed about relevant industry regulations and standards for maintaining compliance and adhering to best practices in food equipment safety

2. Is it compliant?

Supermarket facilities managers shoulder the responsibility of ensuring that food equipment remains compliant with both state and federal guidelines to uphold safety and regulatory standards. This makes it vital to stay well-informed about the specific food industry regulations, such as those established by the FDA and USDA, as well as any state-level health and safety agencies.

Regular audits and inspections of food equipment should be conducted to identify any deviations from these regulations. Keeping meticulous records of maintenance schedules, equipment repairs, and employee training sessions is also critical to demonstrating compliance in case of audits or inspections.

3. Is it operational?

Of course, especially when it comes to high volumes of food production, supermarket FM teams must ensure the seamless operation of food equipment.

To achieve this, they should implement a range of strategic measures throughout the year:

- Regular preventive maintenance schedules to detect and address potential issues before they escalate into unexpected breakdowns

- A robust maintenance checklist that covers critical components of each piece of equipment

- Redundancy plans or backup equipment on hand to mitigate the impact of unforeseen breakdowns

- Staff training in safe and proper equipment usage and troubleshooting to empower employees to address minor issues promptly and minimize downtime

- Close collaboration with suppliers for timely repairs, replacement parts, and technical support to ensure expedited resolution of any equipment-related issues

Additionally, leveraging technology such as predictive maintenance tools and monitoring systems can provide real-time insights into equipment performance and allow proactive interventions to ensure optimal operation at all times.

Together these strategies can help ensure food equipment remains fully operational, even in the face of high production demands.

4. Is it energy-efficient?

Efficient management of energy consumption in food equipment is not only crucial for environmental sustainability but also cost savings. There are a number of steps facilities management teams can take to ensure their food equipment is energy-efficient, including:

- Investing in energy-efficient equipment with high Energy Star ratings

- Implementing regular maintenance schedules, including cleaning and servicing, which ensures equipment operates at optimal efficiency levels

- Installing programmable thermostats, timers, and sensors to regulate equipment usage based on demand, preventing unnecessary energy consumption during off-peak hours

- Educating staff about energy-saving practices, such as proper equipment usage, turning off unused appliances, and maintaining proper temperature settings

- Implementing an EMS (energy monitoring system) for monitoring and tracking energy usage patterns and identifying opportunities for efficiency enhancement

A preventive maintenance program is critical for supporting a store’s sustainability strategy.Cristee Monahan, VP of Central Operations at City

“A preventive maintenance program is critical for supporting a store’s sustainability strategy,” Cristee says. “Whenever we implement a PM schedule, from changing dirty filters to replacing faulty switches or cracked doors, we’re taking active steps to improve energy consumption.”

For more ideas, check out these food retail energy efficiency strategies.

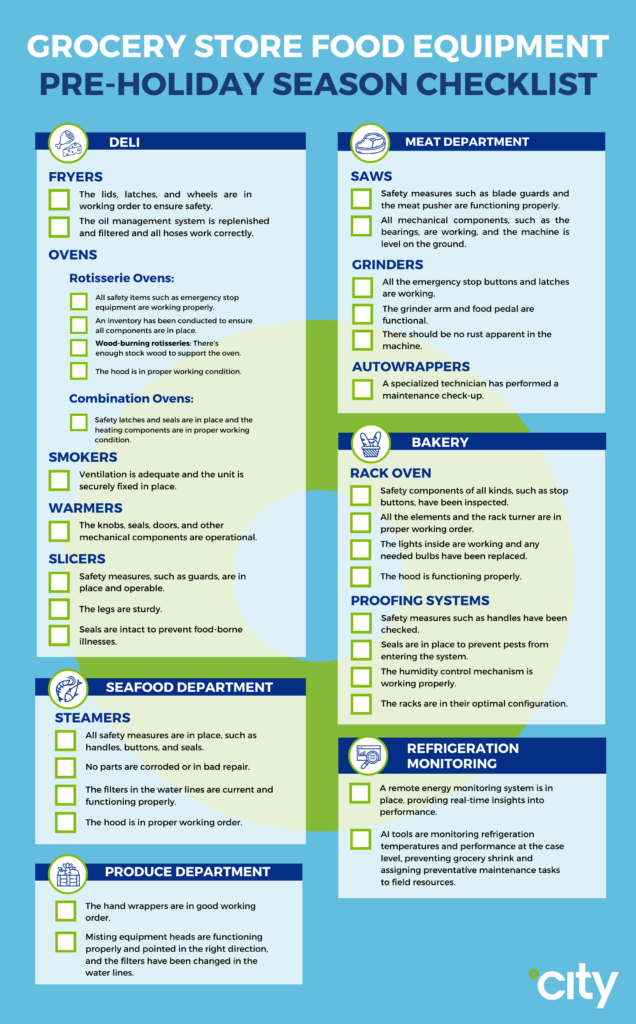

Grocery Store Food Equipment Pre-Holiday Season Checklist

As your team gets ready for the holiday season, make sure to evaluate food equipment using the points above (safety, compliance, operation, and energy efficiency). Below are some of the key elements to look for as part of your food equipment maintenance checklists:

Deli

Fryers

- Verify the lids, latches, and wheels are in working order to ensure safety.

- Make sure the oil management system is replenished and filtered and all hoses work correctly so the product quality is as high as possible.

Ovens

- Rotisserie ovens:

- Make sure all safety items such as emergency stop equipment are working properly.

- Conduct an inventory to ensure all components are in place, such as skewers and burners. For wood-burning rotisseries, stock wood to make sure there’s enough to support the oven.

- Ensure the hood, if there is one, is in proper working condition.

- Combination ovens: Check the machine to ensure safety latches and seals are in place and the heating components are in proper working condition.

Smokers

- Make sure ventilation is adequate and the unit is securely fixed in place.

Warmers

- Ensure the knobs, seals, doors, and other mechanical components are operational.

Slicers

- Ensure safety measures, such as guards, are in place and operable.

- For safety reasons, make sure the legs don’t wobble.

- Check seals to ensure to prevent food-borne illnesses.

Bakery

Rack oven

- Safety components of all kinds, such as stop buttons, should be inspected.

- Make sure all the elements are working as they should and the rack turner is in proper working order.

- Check the lights inside, replacing bulbs as needed.

- If not ventless, ensure the hood is functioning properly.

Proofing systems

- As with ovens, check safety measures such as handles.

- Ensure seals are in place to prevent pests from entering the system.

- Check the humidity control mechanism.

- Ensure racks are in their optimal configuration.

Seafood Department

Steamers

- Make sure all safety measures are in place, such as handles, buttons, and seals. Nothing should be corroded or in bad repair.

- Ensure the filters in the water lines are current and functioning properly.

- Check the hood (if there is one) to make sure it’s in proper working order.

Meat Department

Saws

- Ensure safety measures such as blade guards and the meat pusher are functioning properly.

- Inspect the machine from a mechanical perspective, ensuring the bearings work and the machine is level on the ground.

Grinders

- Make sure all the emergency stop buttons and latches are working — the machine shouldn’t operate when safety latches are open.

- Make sure the grinder arm is functional.

- There should be no rust apparent in the machine.

- Test the food pedal to make sure it’s working properly.

Autowrappers

Autowrappers are a pivotal piece of equipment and often require a proprietary technician for servicing or special certification for self-delivery. Over the summer, schedule a maintenance check-up visit from a specialized technician, who will check safety features, mechanical components, electrical systems, temperature and heat sealing, film supply mechanisms, material handling, sensor calibration, and software and controls. They will also clean and lubricate the machine’s components and test the machine’s operation.

Produce Department

The produce department may not do any cooking for the holidays, but produce staff fulfill a critical function in processing produce and cutting vegetables and fruit for platters.

- Make sure hand wrappers are in good working order.

- Check misting equipment to ensure the heads are functioning properly and pointed in the right direction, and change out the filters in the water lines.

Holiday Refrigeration Monitoring

While not technically food preparation equipment, refrigeration cases also play a vital role during the holidays — and a single breakdown can be devastating in terms of grocery shrink and revenue loss.

Ensuring refrigeration cases operate optimally at appropriate temperatures with no condensation or leakage is an art in itself. This is where remote energy monitoring comes in, as it enables grocery stores to maintain the efficient operation of their refrigeration cases by providing real-time insights into their performance.

For example, City has developed a robust analytics platform that sits on top of EMS systems and targets anomalies in asset specification or energy consumption at partner sites. If temperatures spike or fall outside their expected range, the program sends alerts to facilities managers who can investigate and address issues before food spoils, avoiding costly grocery shrink and equipment repairs. In some cases, problems can even be fixed remotely.

Additionally, AI tools can be used to monitor refrigeration temperatures and performance at the case level, preventing grocery shrink and assigning preventative maintenance tasks to field resources.

Integrated Facilities Management Solutions for Any Season

By implementing the checklist above, FM leaders can avoid costly breakdowns and lower stress while extending the life of commercial food equipment.

At City, we offer an industry-disruptive delivery system for facilities management founded on preventive maintenance that significantly delivers exceptional service and sustained cost savings. Learn more about our integrated facilities management services.

2016: City US is established in North America, in partnership with Southeastern Grocers (SEG), servicing over 750 supermarkets across 7 southern states.

2016: City US is established in North America, in partnership with Southeastern Grocers (SEG), servicing over 750 supermarkets across 7 southern states. 1985: Willie and Susan Haughey establish City Refrigeration Holdings (UK) Ltd in Glasgow, UK.

1985: Willie and Susan Haughey establish City Refrigeration Holdings (UK) Ltd in Glasgow, UK. 2009: City Australia launches in Melbourne, in partnership with Coles, servicing over 700 supermarkets across the country.

2009: City Australia launches in Melbourne, in partnership with Coles, servicing over 700 supermarkets across the country. 2015: City Asia launches in Kuala Lumpur, Malaysia, in partnership with Dairy Farm, servicing over 205 supermarkets across the region.

2015: City Asia launches in Kuala Lumpur, Malaysia, in partnership with Dairy Farm, servicing over 205 supermarkets across the region.